Safety and Efficiency

Ladders are dangerous. But did you know they are also inefficient?

Our fleet of Micro Elevating Work Platforms (ie. MEWPs) make work safer while improving on-the-job efficiency. And let’s face it: larger lifts aren’t always the best choice (for instance in highrise fit-outs). And large drivable lifts can be responsible for damage done to finished work.

Make the switch. Call 888.569.4050

Safety and Efficiency

Ladders are dangerous. But did you know they are also inefficient?

Our fleet of Micro Elevating Work Platforms (ie. MEWPs) make work safer while improving on-the-job efficiency. And let’s face it: larger lifts aren’t always the best choice (for instance in highrise fit-outs). And large drivable lifts can be responsible for damage done to finished work.

Make the switch. Call 888.569.4050

Reading Recommendations

Reading Recommendations

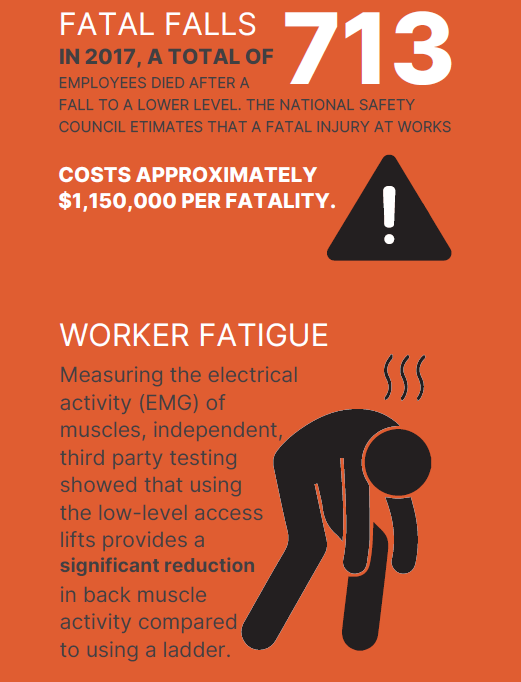

THE HUMAN AND FISCAL COSTS OF LADDERS

MISSED WORK DUE TO INJURY

OCCUPATIONAL INJURIES INVOLVING DAYS AWAY FROM WORK UNITED STATES, 2017

OVEREXERTION,

BODILY REACTION

• Injury rate: 30.0 per 10,000 full-time workers

• Typical days lost: 13

• Most frequent part of body hurt: back

NUMBER OF INJURIES

295,830

FALLS, SLIPS, TRIPS

• Injury rate: 23.1 per 10,000 full-time workers

• Typical days lost: 12

• Most frequent type of injury: sprains, strains, tears

NUMBER OF INJURIES

227,760

EFFICIENCIES & COST SAVINGS of Micro Elevating Work Platforms (MEWPs)

- MEWPs are 3 times more productive than other access equipment

- MEWPs have fewer maintenance problems than other access equipment

- MEWPs provide the lowest repair costs when compared to all other access solutions

- MEWPs are less likely to be abused by the workforce – restricting behavior choices, potentially less supervision needed than other access equipment

- MEWPs currently occupy only 14% of the cost of repair to access equipment

Soure: Gerry Mulholland (HSE Leader- Laing O’Rourke Technologies) Performed an inclusive non-bias study on the selection of work at height solutions. Needing something that could withstand scrutiny Mulholland employed method and theory from ESCP-EAP School of management Consulting and American Society of Mechanical Engineers (ASME) “Process Charts – First steps in Finding the One Best Way”

Built-in Safety Features & Reduction of Fatigue

CLIENT TESTIMONIALS

What impresses me the most about Low-Level Access is their drive and desire to innovate and tackle challenges head on. We struggled with contractors safely and correctly erecting scaffolding systems; the Low-Level Access team brought the game changing MiTower to the table. We identified with our drywall contracting partners the physical abuse their crews were putting on their bodies, and Low-Level Access shows up with a scissors lift that does all the heavy lifting for them. Plain and simple, Low-Level Access is a partner that listens and focuses on the need, not just pushing a product.

Tadd Hilgendorf CSP, ASP, CHST, CHC, CRIS

Division Safety Director

Our company doesn’t like ladders… period. We have always recommended the use of lifts, scissor or boom. When I first saw the Low-Level Access system, I thought it was one of the best new inventions I had ever seen. Lightweight, maneuverable, easy to relocate, non-electric, and very easy to use.

It’s such a no-brainer, it would be difficult to find a reason not to use it.

When we fitted out our main office at the MetLife building midtown Manhattan, we rented 20 lifts. Two different sizes. Our guys and the trades loved them. No more hole in walls when transporting.

When purchasing new contractors the use of this equipment should be written into the contracts. Once good reliable trades use this product they will never go back to extension ladders or big bulky scissor lifts.

Mike Marrone

Director of Operations

Join our Mailing List

Be the first to hear about news, industry trends, and more.

Join our Mailing List

Be the first to hear about news, industry trends, and more.